XLTI utilizes sound process development techniques to ensure product and process quality and soundness:

- Vacuum-assisted to improve casting integrity

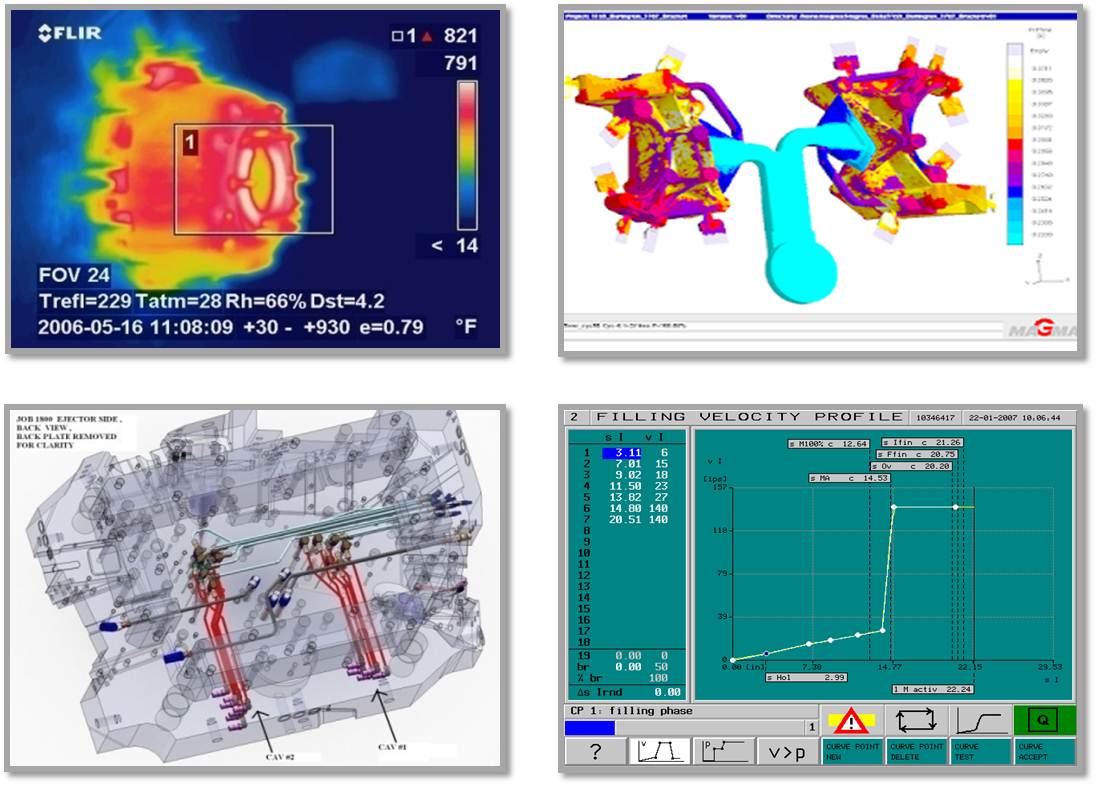

- Flow and thermal simulation to forecast die cavity filling

- Unique shot sleeves for specific applications to extend sleeve and control sleeve temperature

- Proprietary cooling line calculations for new tool design and existing tool analysis

- High-conductivity tooling inserts to remove heat from sprue areas and other “hot spots” in die

- Squeeze pins to reduce shrinkage voids

- Die performance solutions and process optimizations for new and existing tools

- Assistance with launching new programs at customer`s location